Anyway, I've been slowly working on my two straight modules that are a good fit for downtown condo living.

First up ... the eventual 90 degree street intersection track work has been completed.

The turnouts are functional, so with a little creative trimming, I could always expand to the left if I so chose to fit in another module. For now, it will just be a scenic detail.

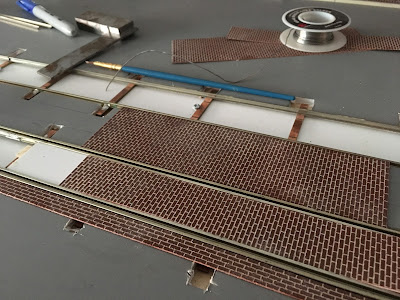

As discussed in prior posts, I am using plastic brick sheeting to pave my streets to keep weight down and mess to a minimum (again with the downtown condo living theme). Therefore, to bring the street up to rail level, I'm laying 3/8" foam core board down. To bring the track into level with the foam core, the track is laid on 0.040" styrene.

Next, 1/16" basswood is laid in the center of the tracks:

On top of the basswood, 0.010" styrene is then laid down:

And finally, JTT Enterprises O Scale Brick sheeting is laid on top of that:

While not perfect for curves (I have yet to solve that problem, I suspect some careful cutting and bending will be used), it is an effective way to pave brick streets with minimal mess. Also, the weight is very light, keeping in mind the portability required for modules.

Additional sections of sheeting are then combined via carefully cutting the brick patterns.

In the below photo, the seams are more visible than they are in person. These sections were not glued down so the seams stand a little proud. In addition, I will be painting and adding additional mortar to assist in camouflaging the seams.